OUR SERVICES

Select a service to learn more

Precision CNC Machining Services

Niagara Precision has been providing precision CNC machining services to customers in both Canada and the US since 1975. We’re a trusted manufacturer and fabricator of components and tooling for industries such as defense, automotive, energy, and aerospace just to name a few.

Our CNC machining capabilities include processes such as 4-axis milling, drilling, turning, threading, broaching and more. Our state-of-the-art facility utilizes three and four axis vertical machining centers as well as CNC lathes, milling, and grinding equipment.

We work with steels, aluminum, brass, bronze, copper, exotic metals, and plastics featuring turning diameters from .125″ to 24″, and up to 60″ long. Accommodating milled components up to 40” in width, 60” in length, and 32” in height, with part weights for both turning and milling up to 1100 lbs., all while maintaining tolerances of ± 0.0002”. We have trusted contacts to help handle additional services such as heat treating, welding, plating and powder coating.

Offering services that go beyond the standard job shop with reverse engineering and prototyping, as well as tool design and product development. To ensure quality products for our customers, Niagara Precision Limited is ISO 9001 certified, N299 Nuclear compliant, and our team has created a lean, continually improving quality culture.

To learn more about all of our precision CNC machining and other capabilities, see the table below or contact us directly.

Precision CNC Machining Capabilities

Machining Processes

Bar Turning

Boring

Broaching

Burnishing

Contour Turning

Counterboring

Countersinking

Drilling

External

Facing

Form Turning

Grinding

Hard Turning

Honing

Internal

Knurling

Milling

Parting/Cutting

Pocketing

Profiling

Reaming

Straight Turning

Taper Turning

Tapping

Thread Milling

Threading

Turning

Equipment & Capabilities

CNC Control Capabilities

Engine Lathes

Grinding Machines

High Speed Machining

Inspection Facilities

Lathes

Reverse Engineering

Vertical Machining Centers

Vertical Milling Machines

Quality Control Systems

We care about our products

As an ISO 9001:2015 certified company, Niagara Precision Limited has established a quality control system in order to meet or exceed customer requirements. This system includes regular gauge calibration, traceable to national standards.

In 2024, Niagara Precision Limited constructed an 18’ x 24’ Inspection Office in our facility. Construction of this space allowed us room for the purchase of a brand new Coord3 12.9.8 CMM with CMM Manager. This joins the Brown & Sharpe 7.10.7 CMM which was retrofitted with Polyworks in 2020, allowing NPL to improve inspection throughput. Complete documentation of inspection reports, as well as material certifications are available based on customer requirements. Niagara Precision Limited is also capable of supplying PPAP and first article inspection.

We are always purchasing the most technologically advanced machinery for quality control to enhance our current systems and practices.

Controlled Goods Program – Certificate

The Controlled Goods Directorate (CGD) administers the Controlled Goods Program, a domestic industrial security program that helps strengthen Canada’s defence trade controls and prevents the proliferation of tactical and strategic assets including weapons, satellite global positioning systems and communications equipment, military equipment and related intellectual property. This is done by regulating and controlling the examination, possession, and transfer of controlled goods and controlled technology in Canada.

Niagara Precision is authorized to examine, possess and/or transfer controlled goods and/or controlled technology and complies with the Defence Production Act and the Controlled Goods Regulations.

Proof of registration is also required for the legal transfer of controlled goods and/or controlled technology. Export permits cannot be issued for controlled goods and/or controlled technology without the CGD Registration Certificate.

Niagara Precision maintains an up-to-date security plan describing the procedures used to control the examination, possession and transfer of controlled goods and/or controlled technology as well as those relating to reporting and investigating security breaches.

The Controlled Goods Program (CGP) is a Federal Government Program administered by the Department of Public Works and Government Services Canada (PWGSC).

Examples of Our Work

At Niagara Precision we provide precision CNC machining services to customers in a wide range of industries. Here are just a few examples of the innovative solutions and value added products and services that we deliver every day.

Development of an Afterburner Lance for the Commercial Furnace Industry

At Niagara Precision, we specialize in precision CNC machining and assembly for customers in a wide range of industries. We were contracted by a manufacturer of commercial furnaces to develop a small-scale water-cooled oxygen injection lance, which was to be used in an experimental smelter. The engineering efforts included complete design and product development including feasibility studies. Because the lance was to be used in the high temperature environment of a smelter, it featured a complex water jacket system.

Composed of stainless steel and copper, components which we machined on our CNC lathe, and 4-axis CNC mill, this allowed us to meet tolerances of ±.001″. After dimensional inspections, the machined components were assembled and brazed. The finished lance had dimensions 24″ in length, 6″ in width and height, and weighed 201 lbs.

Products such as this injector lance are usually produced in Europe, because of our flexible and complete capabilities, we were able to provide this customer with a single source solution, produced domestically. To learn more about this project, see the table below or contact us directly.

Click here for additional project details

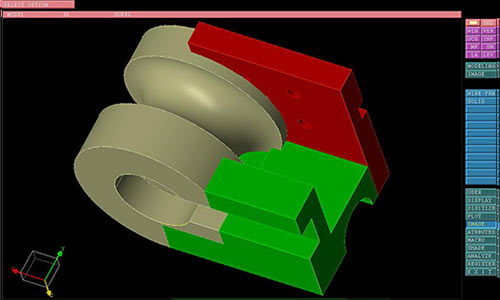

Development and fabrication of a steel alloy bend die for the steel pipe industry

As a full service provider of precision machined components, Niagara Precision provides customers with a single source solution to their custom manufacturing needs. We were contracted by a manufacturer of boilers, to fabricate a die that would be used to bend steel boiler tubes. The customer supplied us with specifications, which we used to engineer the final design. Composed of 4340 steel, the finished die featured dimensions 6″ in length, height, and thickness, with machined tolerances of ±.001″, in addition, it also required a polished finish. After machining and dimensional inspections, the die was then heat treated with a nitriding process, before receiving a surface coating. Although this project is outside of our normal scope of work, we were still able to complete the entire job is just 8 weeks. For more information see the table below or contact us directly.

Click here for additional project details

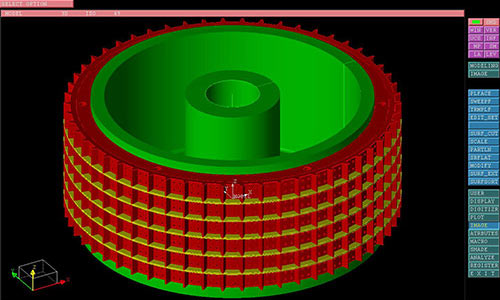

Precision CNC machining of a stainless steel impression die for the food industry

Niagara Precision was approached by a producer of food products to precision CNC machine a rotary impression die, which was designed for use in a cereal manufacturing process. Composed of food grade stainless steel, the specifications required extremely tight tolerances. Final dimensions had to meet tolerances of ±.001″, in addition, the finished piece had to pass functionality testing. Manufacturing required extensive CNC milling and turning and drilling, as well as assembly and fitting of the finished components. Through the manufacturing and assembly process, all parts were subject to stringent quality measures including comprehensive dimensional testing. Completed in only 8 weeks, this product met all of the customer specification, for precision and quality,

To learn more about this project, see the table below or contact us directly.

Click here for additional project details

Large Scale Machining of Steel Doors for a Nuclear Waste Containment Application

The project highlighted here represents a large scale machining effort for Niagara Precision. These doors were designed for use on the front of an X-ray radiation containment structure, and were ultimately installed at a nuclear power facility in Ontario, Canada. From the customer’s specifications, we developed a design and conducted feasibility studies to ensure that the finished product would perform exactly as expected. Composed entirely of structural steel, the design also included a low speed drive mechanism to operate the two 19,000 lb. doors. Each door had a final dimension of 10’ in width, 20’ in length, and 3” thick, which had to be manufactured to tolerances of ±.005”. The machining, all of which was complete in-house, consisted of CNC turning and milling, as well as the use of our boring mill. After extensive dimension and visual inspections the doors were painted, assembled, and put through vigorous functionality testing. This project was designed, manufactured and delivered in 5 months.

To learn more about this project, see the table below or contact us directly.

Click here for additional project details

CNC machined inconel valve stems for the oil and gas industry

At Niagara Precision we specialize in tight tolerance, precision CNC machining. These valve stems are used with extreme condition valves for oil, gas and chemical industry applications. Composed of Inconel, an exotic alloy suited for high temperature applications, the parts also required very tight tolerance machining as well as a high finish. Inconel being an extremely hard material to machine, this project required specialized tooling for the CNC turning needed to manufacture this product. Raw stock was saw cut before moving onto machining, after turning and milling, all parts were deburred before final inspection. At Niagara Precision we take quality seriously, our facility is ISO 9001:2015 certified, as a result everything that we manufacture is subject to stringent quality measures. Parts vary in length from 6″ to 15″, diameters of 3/8″ to 4″, and weighing ¼ to 10 lbs. each. We currently manufacture large quantities of these pieces per year, shipping to this customer in Southern Ontario with lead times of 1 day to 4 weeks.

To learn more about this project, see the table below or contact us directly.

Click here for additional project details

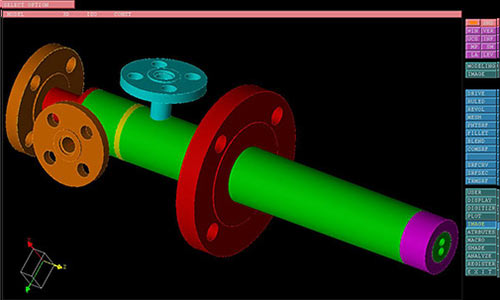

Precision CNC machining of bodies and flanges for the oil and gas industry

We were recently approached by a customer servicing the oil, gas, and chemical industries, who needed a series of products machined from various exotic metals. The bodies and flanges they required were designed for use in extreme conditions, and would utilize material such as Inconel 718, Incoloy 800, Hastelloy C276, Duplex 2205, and titanium. All of these alloys exhibit different machining characteristics, but all required tight tolerances and high finishes.

Machining required precision CNC milling and turning, as well as deburring. Dimensions varied, from 3″ to 8″ in thickness, 3″ to 16″ in diameter, 11 to 200 lbs. Parts were also subject to stringent quality measures, in line with our status as an ISO 9001:2015 certified company. We currently manufacture over 1,000 of these items per year for this customer in Ontario, Canada.

To learn more about this project, or the processes used to manufacture it, see the table below, or contact us directly.

Click here for additional project details

The Roturner Transfer Aid, a medical device for Jaide Products Inc.

The Roturner is a patient transfer aid that was designed and sold in the UK as the “Rotunda”. Niagara Precision Limited now manufactures the Canadian version called the Roturner for distribution through Jaide Products Inc. Please visit the website for more information.